Description

The YPS-300P Yeast propagation station is the professional technological equipment for cultivating of pure culture of brewer’s yeast. The yeast propagation station is designed to cover capacity need of the technically pure yeast culture for a brewery with the yearly capacity of up to 40 000 000 liters.

What is the yeast propagation station for ?

A propagation station acquired by a brewery is an excellent investment into quality of beer. It eliminates the possibility of buying potentially infected yeast; the brewery that owns its propagation station does not depend on their competition, from whom it would otherwise have to take the yeast, and can grow its own yeast culture that would correspond to the character of its beer the best. Due to the stringent requirements for sterility of the whole propagation process, we offer all needed components and aids from the items needed in a laboratory all the way to fermentation vats or tanks and also a separate CIP station.

We can also deliver other versions of completion or arrangement of the below mentioned equipment and accessories, depending on a customer’s request.

Technical description

A subject of this offer is the technological equipment set consisting of the following parts (see schematic):

I. Basic equipment

I.1 Wort steriliser YPS-300

The wort sterilizer is an insulated stainless steel pressure vessel equipped with duplicators for heating and cooling.

For heating we need saturated steam (with 2 bars of pressure), for cooling of sterile wort we use well water in the beginning, and then glycol with the temperature of -4°C. The vessel is equipped by pressure and underpressure fittings, pressure gauge, overpressure drain of condensed steam, which is created during sterilization of the wort, fittings to add air, remote PT 100 thermometer, washing head and appropriate pipe to supply sanitation liquid to sanitize the vessel and all relevant pipes and armatures, lighting, and sight glass located at the upper part of the vessel for visual control of the process taking place inside.

The tangential supply pipe with a jet that is connected to a circulation pump enables to use the vessel as a whirling tank to clean the wort from sludge and other mechanical impurities, whose presence would affect the yeast propagation process in the propagator.

Parameters of the wort steriliser YPS-300 :

- total volume …. 380 liters

- useful volume …. 300 liters

I.2 Propagator YPS-300

This is an insulated stainless steel vessel equipped with cooling duplicator, under and overpressure armatures, barrier device, including a pressure gauge, fully sanitizable sampling cock and inoculation tube to aseptically transfer a pure laboratory culture from a storage vessel to the propagator, supply of sterile pressure air and aerating candle.

The propagator is also equipped by a washing head and the pipe to supply and drain sanitation solutions, PT 100 temperature sensor, and surface level sensors to keep correct liquid levels in the vessel, working platform to safely control the armatures located at the upper part of the vessel and a sight glass with light for visual control of running processes.

Parameters of the propagator YPS-300 :

- total volume …. 380 liters

- useful volume …. 300 liters

I.3 Connection panel YPS-300

This panel serves to arrange individual pipes for filling, emptying and sanitation of individual propagation station vessels and fermentation tanks, the panel also has a UV lamp (with throughput of 10m3/h-1) to sterilize pressure air and the last rinsing water that enters the equipment sanitation system.

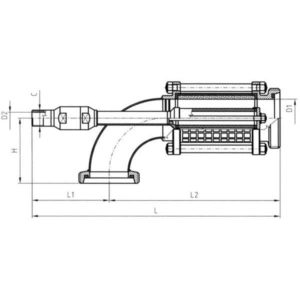

I.4 Pipe connections + wort aerator + pump set YPS-300

This serves to connect the propagator with sterilizer and sanitation station. The equipment has an aerator candle that is installed into the pipe at the sterilizer drain location behind the circulation pump, the tangential supply pipe jet to stir cooled sterile wort and consequently whirl it to support sedimentation of impurities and cooling sludge.

The pipe has a circulation pump (with output Q=1200l h-1 and H=20), which is designated to pump wort between the propagator and sterilizer, and to stir the wort in the sterilizer during sterilization.

I.5 Electrical equipment + wire connections + control and regulation set YPS-300

A part of the delivery is a distribution box connected to a control panel with all control, regulation and signal elements – all this is assembled and fully functional.

Automatic functions that run based on pre-selected parameters:

-heating of sterilized wort,

-cooling of individual vessels,

-aerating of fermenting wort in the propagator,

-monitoring of levels in individual vessels

I.6 Support frame YPS-300

This is basic frame that supports all propagation station equipment.

I.7 CIP station YPS-300

The CIP station is dedicated equipment for cleaning, sanitizing and sterilisation all parts of the yeast propagation station that are in contact with yeast.

- 1 stainless steel insulated vessel with heating /either steam heat exchanger, or electrical source/ and regulation of temperature for alkaline sanitation, including appropriate fittings,

- 1 stainless steel vessel without heating for acidic sanitation, including appropriate fittings,

- stainless steel circulation pump to pump sanitation solutions

(H=30 m, Q=1500 l h-1) to the washing heads in propagation station vessels and fermentation tanks,

- mobile stainless steel circulation pump for backward sanitation (H=25m, Q=1200 l h-1),

- supply of cold and warm water – the pipe inlet is on the suction side of delivery pump, the water is used to rinse the pipes between individual disinfection and sanitation steps, the water main is connected to the UV lamp.

Parameters of CIP YPS-300 :

- Vessel with heating (total / useful volume ) …. 150L / 180L

- Vessel without heating (total / useful volume ) …. 150L / 180L

I.8 Fermentation tank YPST-300-FT-X000

This is a stainless steel insulated vessel, with cooling 2 duplicators and control of fermenting process temperature in the fermentation tank, under- and overpressure armatures, pressure gauge, fully sanitizable barrier device and sampling cock, level sensors, washing head, supply and drain pipes for sanitation solutions, entrance opening and remote PT 100 thermometer. Working pressure in tank: 1.5 bar.

We offer four variants of the fermentation tank YPS-300 :

- FT 1000 …. useful volume / total volume 1000L / 1250L

- FT 2000 …. useful volume / total volume 2000L / 2500L

- FT 3000 …. useful volume / total volume 3000L / 3670L

- FT 5000 …. useful volume / total volume 5000L / 6400L

II. Recommended services related to the supply of equipment

II.1 Installation Supervision 1 worker

Installation is provided in the form of installation supervision (1 workers for 6 days ) with the provision that the Purchaser will provide accommodation for the Supplier assembler, Assembly price is 25,- EUR per hour.

Their transportation costs (airline tickets), manipulation equipment and qualified assemblers, who will do especially welding and electric installation work in agreement with local regulations, at his own cost.

- Usual price of this service in Europe … 2000 Eur

II.2 Commissioning and Personnel Training

A supplier‘s engineer will test the equipment and put it into operation after assembly. Then he will train the service personnel 5-6 days.

A part of this service can also be a delivery of the agreed yeast culture that will be propagated in the propagation station.

- Usual price of this service in Europe … 2200 Eur

III. Optional accessories

III.1 Modified keg 20L

replaces Carlsberg bottle / stainless steel pressure vessel to transport pure laboratory culture, the culture from the keg gets injected to the propagator. Volume: 20 liters.

- Price …. 698 Eur

The below specified accessories is available according to wishes and needs of a Customer:

III.2 Carlsberg Bottle

A special bottle for transport of pure laboratory culture, the culture from the bottle gets injected to the propagator. Volume: 15 liters

- Price …. 6600 Eur

III.3 Portable oxygen meter

Equipment to measure O2 dissolved in wort that is used to fill the propagator and fermentation tanks.

- Price …. 11370 Eur

Payment conditions :

- 50% advance within 5 days after signing of contract

- 40% advance 7 days before transport

- 10% within 14 days installation of supervision however, 4 month after shipping at the latest

Delivery deadline:

- 3-5 moths after signing contract and receiving payment to our account

Reviews

There are no reviews yet.