Description

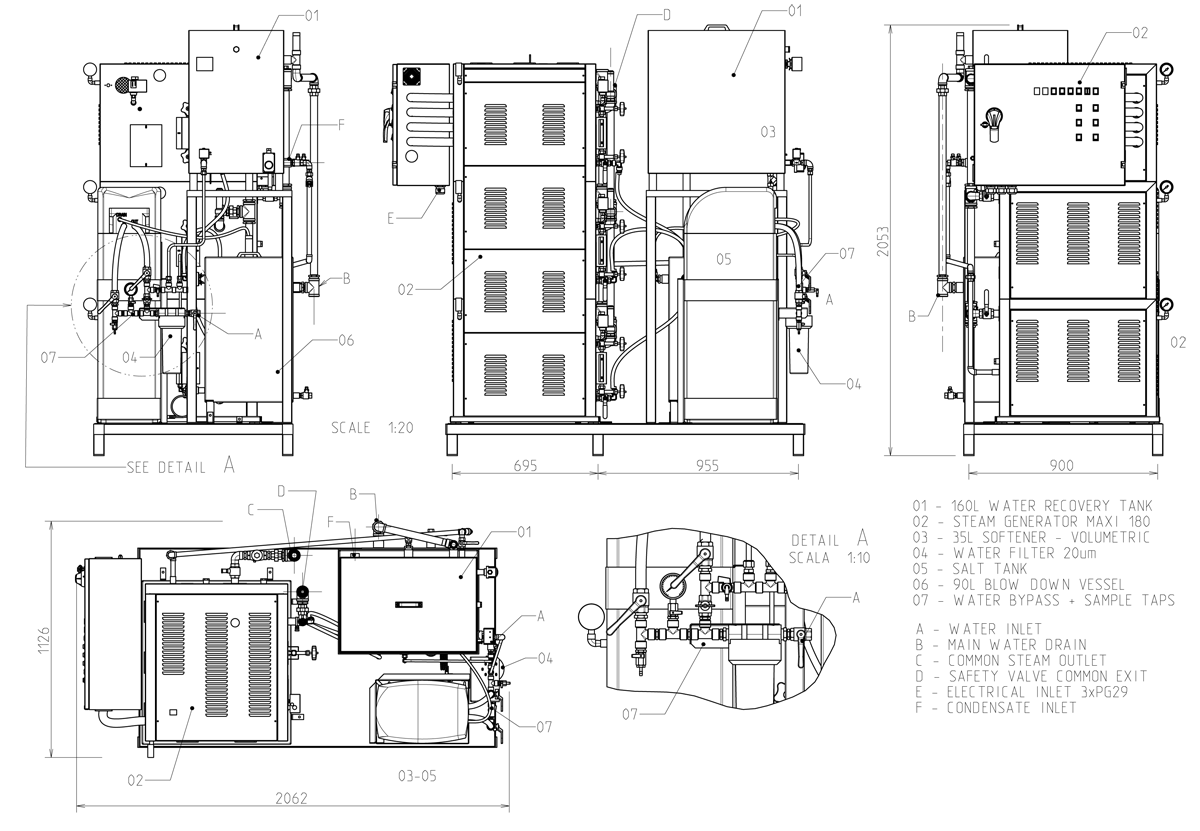

Automatic electric hot steam-generator – the complete system on the frame

The compact build pre-assembled and tested steam generator with all recommended accessories. All is delivered on the stainless steel frame, with all internal connections, ready-to-use.

The compact system includes a complete water treatment, a condensation recuperation system and a boiler sludge draining system (cooling tank for desilting the steam generator boiler) .

This type of execution makes it possible to minimize both dimensions and on-site installation costs and start-up activities. Once it is set in its installation point, the whole equipment only needs to be connected to the essential utilities, such as electric power supply, steam output pipes and water distribution.

Regulation of the working steam pressure is adjustable in range from 1 to 4.5 or 8.5 bar (it depends on the version ordered).

This steam-generator is available with six independent heaters (six independent heating elements). The steam-generator shell is manufactured in accordance to the current PED regulations.

Made in Italy

Recommended use :

- Heating the wort brew machines – recomended for brewhouses with maximal usage volume 2000 liters per one brew

- Heating the water, beverages or chemical solutions in the water tanks, CIP stations, boilers, pasteurisers etc.

- Heating the food processing machines

- Sterilization of the vessels, pipes, hoses, stainless steel kegs, filters, food production equipment, farmacy equipment … with hot steam

Parameters and accessories :

| Technical data | Model : MXSG-150CSF : GHIDINI MAXI-180 25-150kW + recommended accessories |

| Capacity | Switcheable : 25 / 50 / 75 / 100 / 125 / 150 kW (32 kg up to 195 kg of hot steam per hour) |

| Pressure and temperature of outgoing steam (4.5 bar version) | From 1 bar to 4.5 bar / From 100°C to 155°C |

| Pressure and temperature of outgoing steam (8.5 bar version) | From 1 bar to 8.5 bar / From 100°C to 177°C |

| Power supply voltage and frequency (EU version) | 3-phases 380-420V / 50 Hz |

| Power supply voltage and frequency (US version) | 3-phases 220-240V / 60 Hz |

| Boiler capacity | 3x 55 liters |

| High temperature pump | 0.55 kW |

| Electric heaters | 6x 25 kW |

| Safety overpressure valve | 5 bar or 9 bar (depending on the version) |

| Water inlet | BSP 1/2″ (ET) |

| Condensate return (only if the condensate recovery set is included) | BSP 1/2″ (ET) |

| Total dimensions (without the condensate recovery set) | L x W x H : 1712 x 910 x 2053 mm |

| Net weight | 400 kg |

| Gross weight (without the condensate recovery set) | 480 kg |

| Packing dimensions with the palett (without the condensate recovery set) | 1800 x 1000 x 2280 mm |

Optional equipment :

| CT-MX180 : Stainless steel tank for returned condensate 160L, including level sensor, solenoid valve and thermostat (for MAXI 150/180) | included |

| CT-MX180S : Stainless steel tank for returned condensate 160L, including level sensor, solenoid valve and thermostat | all components in contact with water are made in stainless steel (for MAXI 150/180) | € 2250,- |

| CTMK-MX : Kit to mount the condensate recovery tank above the steam generator (for MAXI 150/180) | included |

| CSW304-MX180 : All components of the steam generator in contact with water in stainless steel AISI 304 (for MAXI 150/180) | € 11150,- |

| CSW316-MX180 : All components of the steam generator in contact with water in stainless steel AISI 316 (for MAXI 150/180) | € 11788,- |

| TSD-MX180 : Cooling tank with the boiler sludge draining system (for MAXI 150/180) | included |

| ASR-MX180 : Automatic sludge removal (for MAXI 150/180) | € 2213,- |

| WTS-MX180 : Water treatment system – necessary to prevent damage to the machine by mineral deposits (for MAXI 150/180) | included |

| SKID-MX150 : The complete compact solution on the frame : Cooling tank with the boiler sludge draining system + condensate tank + water treatment system + stainless steel frame + all pipe connections (for MAXI 150) | included (this system) |

Warranty : 12 months (for all parts) – A customer with help of our remote support identifies a bad component and then send it to us. Then a spare part will be sent to the customer.

On-site repair services are not included.

Delivery time : from 7 days to 8 weeks (according current store status)

Reviews

There are no reviews yet.