Description

The automatic line for the filling and washing of stainless steel kegs with production capacity from 50 to 68 kegs per hour.

The machines are designed and made with special care paid to hygiene and available in different sizes and models. The entire structure of the machine and the parts that are contact with the liquid are entirely made out of AISI 304 stainless steel.

The filling head was conceived with careful detail to exclude any type of contact with air on the part of the product being worked and to ensure a filling that’s completely sterile.

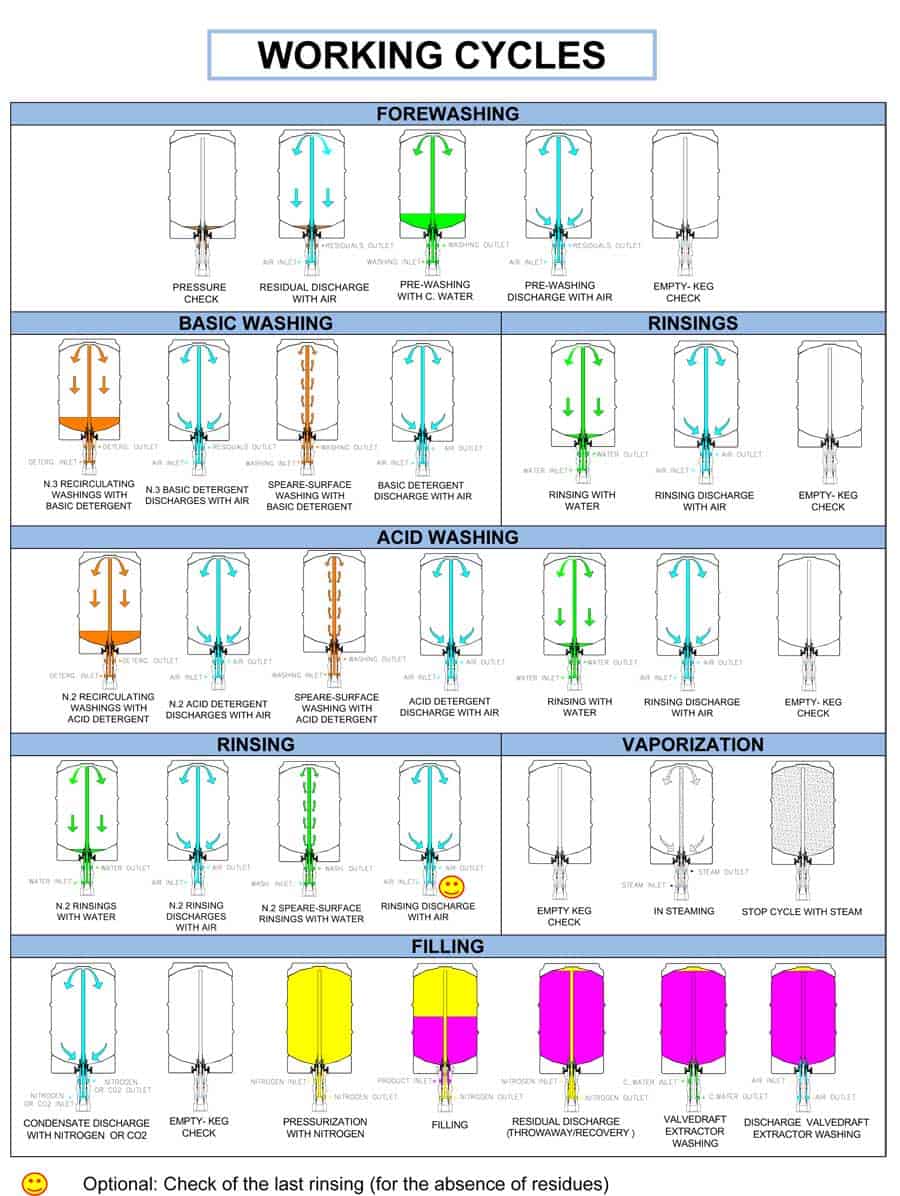

The washing systems were conceived to ensure:

a) A good cleaning

b) The checking and monitoring of the rinsing phase

c) at the end of every work phase, the checking for the absence of liquid in the kegs, thus confirming the impossibility of unwanted rackings to then be able to provide the assurance that the discharge phase has occurred.

The systems are fitted for the connection with a steam-generator for hot sterilization of the containers. The command and control parts are positioned in a watertight control board and electronically managed thanks to the use of a PLC.

Our valves for the controlling of the washing and filling cycles are made out of turned-ingot stainless steel and, thanks to their perfect internal finishing, allow for easy washing and sterilization, thereby preventing filth and grime from settling. In addition, the special solid steel

structure guarantees excellent resistance to wear and minimizes the need for ordinary maintenance operations.

| KWFL-MB21A | KWFL-MB31A | KWFL-MB41A | |

|---|---|---|---|

| CHARACTERISTICS | |||

| Filling capacity range | 10-50 l | 10-50 l | 10-50 l |

| Designed for product | Beer | Beer | Beer |

| Washing heads | 2 | 3 | 4 |

| Filling heads | 1 | 1 | 1 |

| Liter counter - accuracy | ± 0.20% | ± 0.20% | ± 0.20% |

| Average filling accuracy | ± 1.5% | ± 1.5% | ± 1.5% |

| Accident-prevention protection | Barriers with stop blocks | Barriers with stop blocks | Barriers with stop blocks |

| Sanitization – sterilization | Water-chemical-Steam | Water-chemical-Steam | Water-chemical-Steam |

| PRODUCTION | |||

| Maximal capacity - for 20/30L kegs | 40 | 50 | 68 |

| Maximal capacity - for 50L kegs | 30 | 40 | 50 |

| CONSTRUCTION MATERIALS | |||

| Construction material | Aisi 304 L | Aisi 304 L | Aisi 304 L |

| Material in contact with the liquid | Aisi 304/316L | Aisi 304/316L | Aisi 304/316L |

| DIMENSIONS AND WEIGHT | |||

| Height of the work table (mm) | 870 | 870 | 870 |

| Dimensions WxDxH (mm) | 4970x1600x2400 | 4970x1600x2400 | 4970x1600x2400 |

| Weight (Kg) | 1050 | 1230 | 1600 |

| ELECTRICITY | |||

| Filler’s installed power (kW) | 3 | 3 | 3 |

| Power of the heating if is present (kW) | 4.5 | 9 | 9 |

| Electric power supply system | 400V 3/pe 50Hz | 400V 3/pe 50Hz | 400V 3/pe 50Hz |

| CONSUMPTION | |||

| Maximal liquid flow rate (l/h) | 3600 | 3600 | 3600 |

| Product pressure (bar) | 2.5 | 2.5 | 2.5 |

| Air pressure (bar) | 6 | 6 | 6 |

| Air consumption ( l/min) | 1350 | 1350 | 1350 |

| Nitrogen pressure (bar) | 6 | 6 | 6 |

| Nitrogen consumption ( l/min) | 300 | 335 | 365 |

| Water pressure (bar) | 3 | 3 | 3 |

| Water flow rate (liters/hour) | 2300 | 2300 | 2300 |

| Heating steam (kg/h) | 24 | 24 | 24 |

| Sterilization steam (kg/h) | 23 | 25 | 27 |

| CONNECTIONS | |||

| Product | DN 25 F | DN 25 F | DN 25 F |

| Compressed air | ½” F gas | ½” F gas | ½” F gas |

| Nitrogen | ⅜” F gas | ⅜” F gas | ⅜” F gas |

| Detergent-heating steam | ½” F gas | ½” F gas | ½” F gas |

| Sterilization steam | ½” F gas | ½” F gas | ½” F gas |

| Water | ¾” F | ¾” F gas | ¾” F gas |

KWFL-MB41A includes :

- Stainless steel frame

- AISI 304/316 L stainless steel product piping

- AISI 304 L stainless steel control board

- Adjustable supporting feet

- Automatic keg type regulator via pneumatic centering device

- Washing and filling function via PLC

- Transfer of the kegs through a beam detector

- Keg centering device

- Operator interface with touch screen

- Liquid-detection sensor at each rinsing, washing and steaming phase (no condensation)

- Keg-detection sensor (on washing-and-filling head)

- Filling with pressure sensor and maximum liquid-level detection

- Detergent heating via steam pocket or electrical resistance – By choice

- Accident-prevention protection with barriers and door-closure monitoring sensor

- Electrical outlet for connection to the feed pump

- 250 liter CIP (Clean-in-place) tank for basic detergent

- 250 liter CIP (Clean-in-place) tank for acidic detergent

- Pump for the re-circulation of the basic detergent

- Pump for the re-circulation of the acidic detergent

- Kit for the washing and sanitization of the filling heads

- Use and maintenance manual in Italian and English

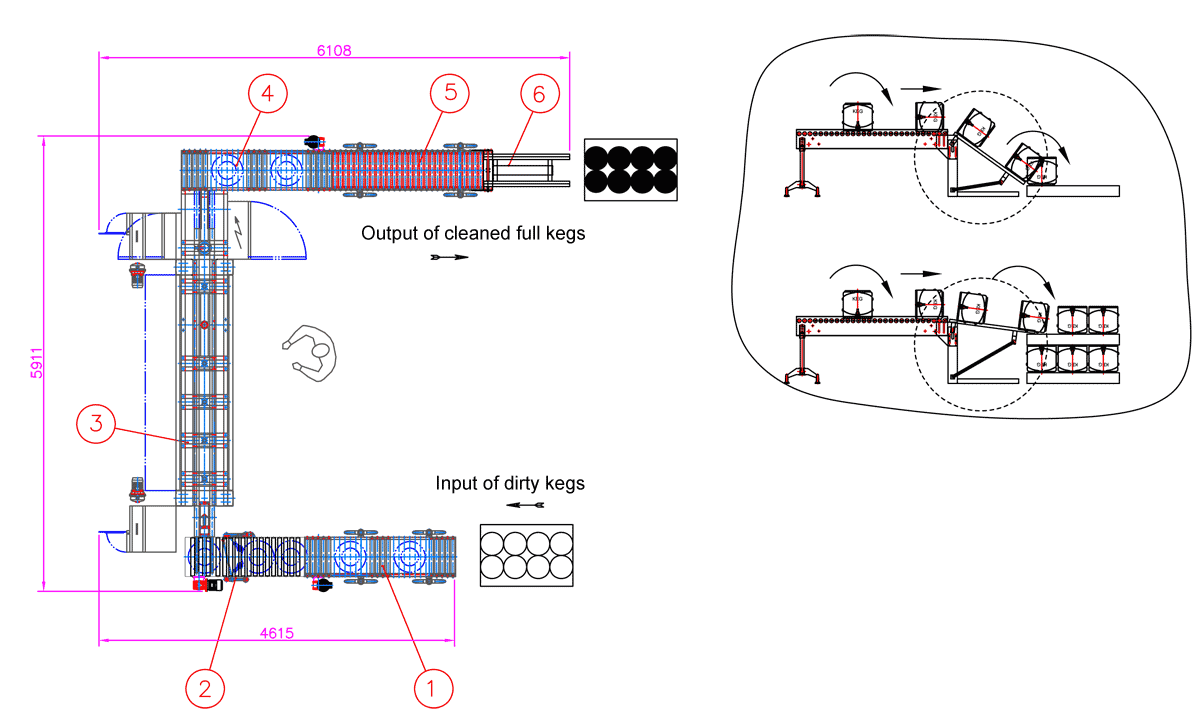

Layout :

This arrangement includes :

——————————————————————————

126k045 1 Idle roll-conveyor – 2000 mm … 3.303 Eur

126k137 2 Motorized roll-conveyor – L pro 1500mm … 5.157 Eur

126k030 2 Line Keg Stopper … 1.464 Eur

126k016 3 Keg filling machine mod. KWFL-MB41A … 92.400 Eur

126k004 / Keg-probe and filling head rinser … 1.197 Eur

126k139 4 Motorized roll-conveyor 2000 mm inox … 6.678 Eur

126k043 5 Single Pincer keg dumper … 14.950 Eur

126k045 6 Idle roll-conveyor – 2000 mm … 3.303 Eur

Metal perimetric protection + doors … 1.550 Eur

Total price … 130.002 Eur

Start up

Start up filling kegs system 1 person for 4/6 days (travel, board and lodging) … About 2.500 – 4.500 euro for EU

Optional

2S5181507T9 Nitrogen Cartridge … 183 Eur

120GC002 Nitrogen Housing … 514 Eur

120V110 Steam Housing … 846 Eur

2B-2001-10 Steam cartridge … 277 Eur

126k038 Semiautomatic stacker (7) … 7.740 Eur

12706 Steam generator 18 kW … 8.778 Eur

126k037 Magnetic liter counter … 2604 Eur

126k070 Pressure check sensor … 2709 Eur

13165 Network router … 1696 Eur

126k032 Last rising conductor-controller check … 7.528 Eur

126k076 Mobile centrifugal feed pump 2.5 bar … 2.037 Eur

126k020 Client keg modification 2sp.+t° … 550 Eur

Optional accessories

| CODE | ACCESSORIES | NOTES |

|---|---|---|

| 126k100 | KWFL-MBx1A 500 l buffer tank for pasteurization | Price available on request |

| 126k041 | Pasteurizer | Price available on request |

| 126k101 | CIP (Clean-in-place) 2x500 liters | |

| 126k102 | CIP 3x500 liters for masterkeg pro | |

| 126k103 | CIP 4x500 liters | |

| 126k033 | 500 L additional tank for the recovery of cold water | |

| 126k034 | 160 L last-rinsing recovery tank | |

| 126k105 | CIP washing connection to one KWFL-MBx1A filling line with 3 tanks | |

| 126k106 | CIP washing connection to one KWFL-MBx1A filling line with 4 tanks | |

| 126k107 | CIP washing connection to two KWFL-MBx1A filling line with 3 tanks | |

| 126k108 | CIP washing connection to two KWFL-MBx1A filling line with 4 tanks | |

| Product microfiltration system | ||

| 2s-5181507t9 | Sartofluor filter cartridge 0.2 um -mini | |

| 2b-1001-ra | Coalescence filter cartridge 5" | |

| 120gc002 | Gas/coalescence housing in aluminum/AISI 316 stainless steel | |

| 120gc001 | Gas/coalescence housing in A 316 stainless steel | |

| 120v110 | Steam housing 1x10" att. | |

| 2b-2001-10 | AISI 316 stainless steel steam filter poc 4um -21- 10" | |

| 126k049 | Acid detergent check | |

| 126k050 | Basic detergent check | |

| 126k032 | 2000 conductor-controller check | |

| 126k070 | Pressure check sensor | |

| 126k037 | Magnetic liter counter | |

| 126k037-utf | Magnetic liter counter; lead sealable - utif model | |

| 13129 | Modem + tele-assistance kit | |

| 13161 | Tele-management of gsm alarms | |

| 13165 | Network router | |

| 13166 | Network router + sms (sim) | |

| 126k019 | Keg pressure control station | |

| 126k075 | Feed pump; upon request | Price available on request |

| 126k004 | Keg-probe and filling head rinser | |

| 126k055 | Additional head. Keg-probe rinser | |

| 126k022 | Full-keg counter | |

| 126k051 | Check for the presence of the keg probe | |

| 126k098 | Recovery of product residues at start of work | |

| 126k040 | Kit for pasteurizer recirculation washing | |

| 126k118 | 1.5 m stainless steel coated idler roller conveyor | |

| 126k117 | 1.5 m zinc-plated idler roller conveyor | |

| 126k045 | 2 m. stainless steel coated input/output idler roller conveyor | |

| 126k046 | 2 m. zinc-plated idler roller conveyor | |

| 126k116 | 3 m. stainless steel coated idler roller conveyor | |

| 126k111 | 3 m. zinc-plated idler roller conveyor | |

| 126k109 | 1.5 m zinc-plated motorized roller conveyor; in sx-dx out dx-sx | |

| 126k110 | 1.5 m zinc-plated motorized roller conveyor; in dx-sx out sx-dx | |

| 126k112 | 2 m zinc-plated motorized roller conveyor; in sx-dx out dxsx | |

| 126k113 | 2 m zinc-plated motorized roller conveyor; in dx-sx out sxdx | |

| 126k114 | 3 m zinc-plated motorized roller conveyor; in sx-dx out dxsx | |

| 126k115 | 3 m zinc-plated motorized roller conveyor;in dx-sx out sxdx | |

| 126k068 | 2 m zinc-plated motorized roller conveyor | |

| 126k067 | 2 m. stainless steel coated motorized roller conveyor | |

| 126k077 | 3 m zinc-plated motorized roller conveyor | |

| 126k072 | 3 m. stainless steel coated motorized roller conveyor | |

| 126k119 | 0.9 m zinc-plated motorized roller conveyor; sx-dx gate | |

| 126k121 | 0.9 m stainless steel coated motorized roller conveyor; sxdx gate | |

| 126k120 | 0.9 m zinc-plated motorized roller conveyor; dx-sx gate | |

| 126k122 | 0.9 m stainless steel coated motorized roller conveyor; dxsx gate | |

| 126k039 | 2 m. stainless steel covered motorized belt | |

| 126k058 | 1.5 m motorized input belt with keg stopper | |

| 126k031 | 2 m. motorized input belt with keg stopper | |

| 126k036 | Motorized belt with 90° bend | |

| 126k035 | 90°-bend idler roller | |

| 126k133 | Motorized gate with zinc-plated rollers | |

| 126k134 | Motorized gate with stainless steel rollers | |

| 126k042 | Ground keg dumper p.s. | |

| 126k044 | Dual-pincer keg dumper | |

| 126k043 | Single-pincer keg dumper | |

| 126k028 | Line checkweigher | |

| 126k027 | Line checkweigher with diverter | |

| 126k015 | Masterkeg pro tare/gross scale on the side of the machine | |

| 126k062 | Keg pusher | |

| 126k073 | Masterkeg pro centering device for kegs on the roller conveyor | |

| 126k030 | Line keg stopper | |

| 126k096 | End-of-the line manual keg facilitator | |

| 126k020 | Client keg modification 2sp.+t° | |

| 126k089 | Yellow netting safety barrier, 1000 h.1900 | |

| 126k090 | Protective safety door 800x1900 w/micro | |

| 126k097 | Capsule distributor | Price available on request |

| 126k054 | Thermal head for seals | |

| 126k052 | Labeler via seal | Price available on request |

| 12804 | Delfino macero washer | |

| 12803 | "Niagara" washer with fixed sprays kegs | |

| 12810 | Rotojet washer with rotating nozzles 01-14 uk 7 | |

| 126k005 | General switchboard X multiple plants masterkeg pro | Price available on request |

| 126k002 | Automated robot palletizer/depalletizer | Price available on request |

| 126k038 | Semi-automatic stacker | |

| 126k123 | Varnished metal perimetric protection 1000 h.1900 | |

| 126k124 | Varnished metal perimetric protection 1200 h.1900 | |

| 126k125 | Varnished metal perimetric protection 1500 h.1900 | |

| 126k126 | Varnished metal perimetric protection 700 h.1900 | |

| 126k127 | Varnished metal perimetric protection 800 h.1900 | |

| 126k128 | Varnished metal perimetric protection 400 h.1900 | |

| 126k129 | Varnished metal perimetric protection 250 h.1900 | |

| 126k130 | Varnished metal perimetric door 800 h.1900 | |

| 126k131 | Varnished metal perimetric door 700 h.1900 | |

| 126k132 | Varnished metal perimetric sliding door 800 h.1900 |

Reviews

There are no reviews yet.