Description

CCT-SHP-250DE is the high-pressure cylindrically-conical fermentation tank with recommended usable volume 250 liters and total volume 300 liters for fermentation, maturation (and also storage, filtering, bottling, filling into kegs) of beer, cider, wine and other beverages. Made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0.0bar to 3.0bar, noninsulated, with water(or glycol) cooling double jacket.

The tank is completely made in Germany.

This offer and price includes the tank which is equipped with the most common equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional equipment”

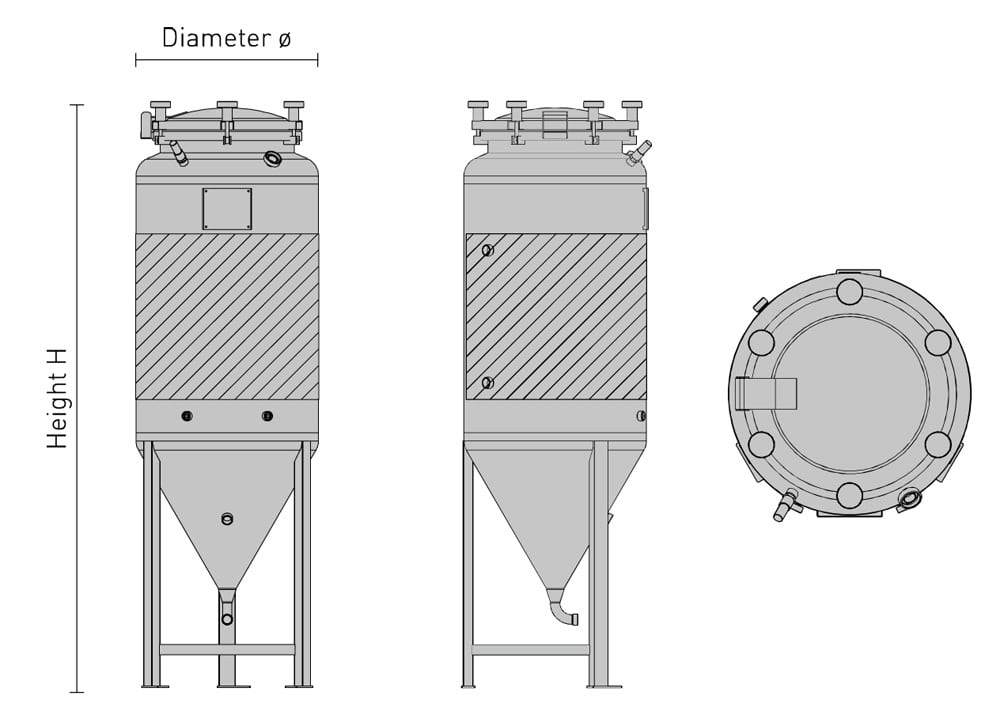

Dimensions

Cooling jackets scheme – the tank includes only one independent cooling jacket (on the cylindrical part) with welded inlets/outlets 2x G 1″ for connection of external cooling/heating water/glycol source.

| Usable volume – recommended [liters] | 250 |

| Total volume [liters] | 300 |

| H – Total height [mm] | 2405 |

| D – Total diameter [mm] | 630 |

| Weight of empty tank [kg] | 169 |

| Weight of full tank [kg] | 464 |

Standard properties and equipment

| Description | Included |

|---|---|

| Maximal allowed overpressure | 3.0 bar |

| PED 2014/68/EU certificate | yes |

| Material | AISI 304 |

| Surface inside | Illc / Illd |

| Outer surface | marbled or brushed |

| Cone angle | 60° |

| Cooling jacket in the cylindrical part (with welded threads 2xG1″) | 0.9 m2 |

| Cooling jacket in the conical part (with welded threads 2xG1″) | no |

| Lifting lugs for transport in tow | yes |

| Top manhole (filling dome) with flap lid | DN400 3.0bar |

| Clear product drain outlet (connection thread) | DN40 / NW40 |

| Complete content drain outlet (connection thread) | DN40 / NW40 |

| Cleaning spray head 360° (connection thread) | DN40 / NW40 |

| Sampling outlet (connection thread) | DN10 / NW10 |

| Temperature measuring socket | DN10 / NW10 |

| Handles for safety ladder | yes |

| Safety ovepressure valve on tank top | 3.0 bar |

| Legs [pcs] | 4 |

| Type plate on tank edge | yes |

Equipment included in this tank set (in the price)

| Description | Included | Alternatives |

|---|---|---|

|

Valve DN40/DN40 | Other types |

|

Valve DN40/DN40 | Other types |

|

Valve DN40/DN40 | Other types |

|

HBA-SCK-02 | Other types |

|

PAA2-DN25 | Other types |

|

Thermometer TMA-125 | Digital control |

|

AFS-4M20 | — |

Optional equipment (accessories for surcharge)

| Description | Recommended | Alternatives |

|---|---|---|

|

FLI-DN10-1 | — |

|

FLI-SC1 | — |

|

TEA-SSP-02 | — |

|

CLC-03 | — |

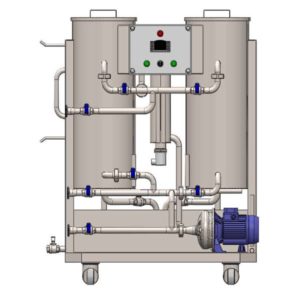

Water-glycol cooler for more tanksWater cooler from 0.85 to 72 kW for simultaneous cooling more tanks. You need also use the measuring and temperature control system. |

CWC-C45MLT | Other types |

|

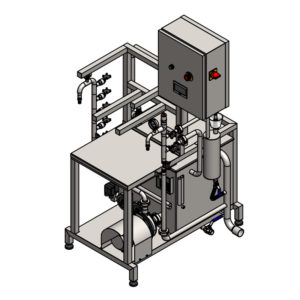

On-tank system | Off-tank system |

|

— | |

|

ACOS-02 | Other types |

|

TSE-SDN150 | Other types |

| Other equipment and accessories for our tanks according of individual customers requirements | Accessories | — |

Recommended use

| Usable for the fermentation process | yes |

| Usable for the maturation process | yes |

| Usable for the storage of the finished product | yes |

| Usable for the non-pressure product flotation | yes |

| Usable for the product clearing under pressure | yes |

| Usable for the product filtration under pressure | yes |

| Usable for manual filling of the product into kegs | yes |

| Usable for manual filling of the product into bottles | yes |

| Usable for machinery filling of the product into kegs | yes |

| Usable for machinery filling of the product into bottles | yes |

How to choose the right type of CCT ?

| Type of CCT | CCT-SNP | CCT-SLP | CCT-SHP |

|---|---|---|---|

| Maximal adjustable pressure in the tank | 0.0 bar | 1.2 bar | 2.5 bar |

| Usable for the fermentation process | yes | yes | yes |

| Usable for the maturation process | no | yes | yes |

| Usable for the storage of the finished product | no | yes | yes |

| Usable for the non-pressure product flotation | yes | yes | yes |

| Usable for the product clearing under pressure | no | yes | yes |

| Usable for the product filtration under pressure | no | no | yes |

| Usable for manual filling of the product into kegs | no | yes | yes |

| Usable for manual filling of the product into bottles | no | yes | yes |

| Usable for machinery filling of the product into kegs | no | no | yes |

| Usable for machinery filling of the product into bottles | no | no | yes |

Our recommendation:

If you are comparing our prices with competitors, please always make sure that any other manufacturer guarantees the same quality as our company offers.

Cleaning-sanitizing pipe

Cleaning-sanitizing pipe Pure-product output pipe

Pure-product output pipe Sampling cock

Sampling cock Apparatus with pressure adjustment

Apparatus with pressure adjustment Temperature measurement

Temperature measurement Adjustable feet

Adjustable feet Filling level indicator

Filling level indicator Cleaning bridge for level indicator

Cleaning bridge for level indicator Sampling spiral

Sampling spiral Water-glycol cooler for cooling one tank

Water-glycol cooler for cooling one tank Temperature measuring & control system

Temperature measuring & control system Compact temperature controller – one tank

Compact temperature controller – one tank Carbonization-oxygenation equipment

Carbonization-oxygenation equipment Stirring device flange on the side

Stirring device flange on the side