Description

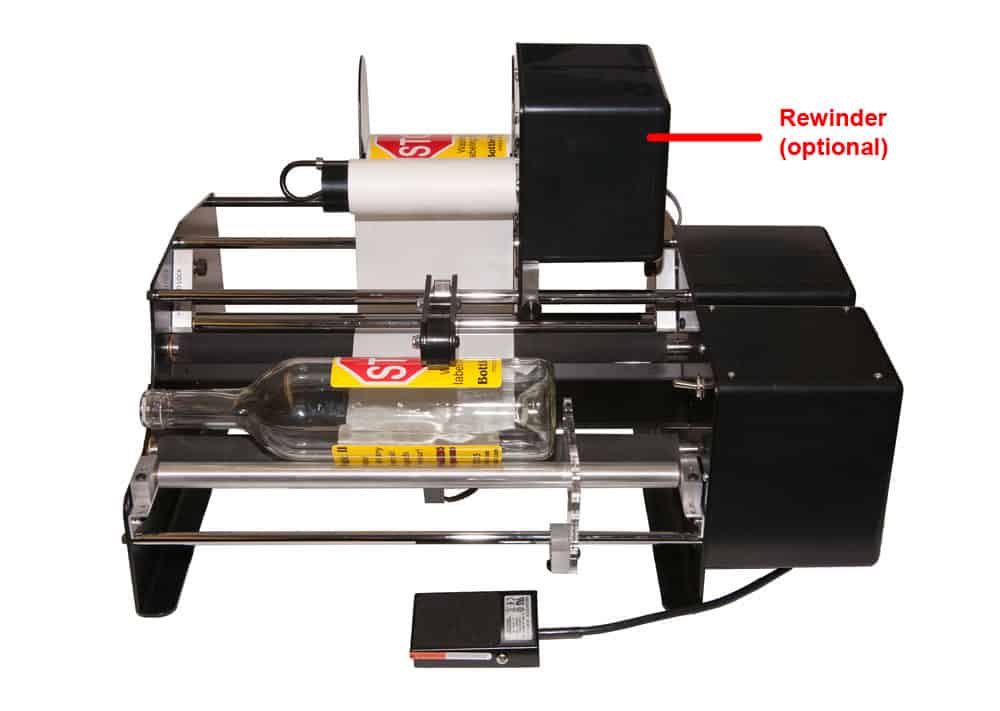

Semiautomatic bottle labelling machine for applying two self-adhesive labels : Model BLM-BM1202

The BLM-BM12012 Label Applicator enables the user to label all kinds of cylindrical bottles by simply inserting the bottle and pressing a foot switch. Once the foot switch is activated the label is applied within 4.5 second, most bottles are labeled in less than 2 seconds! This allows the user to quickly remove the bottle and insert another to start the procedure again. Once a rhythm is established bottles are labeling very quickly. Therefore this bottle labeller can label bottles at speeds up to 1200 Pieces an hour!

The version includes two positions for rollers with paper labels. The machine is able to apply two labels on bottle wihin one cycle.

Product details and characteristics:

- The machine labels cylindrical bottles from 0.5″ to 6″ diameter (from 13 mm to 152 mm).

- Accuration: The machine holds very high side-side accuracy on most bottle types.

- Labeling bottles with length of the cylidric part up to 15″ (381 mm)

- The machine is able to handle most tapered bottles by simply adjusting the idle roller position.

- The machine labels over 1200 pcs per hour with average dexterity of the human operator. (Or more if you have a fast employee)

- Physical trigger into optical sensor activated, will work on all kinds of labels.

- Side frames are cutted by laser from the quality steel which was be formed, cutted and inspected one at a time by our producer.

- Dispensing tables: They are formed out of 6061-T6 Aluminum. The peel edge is hand milled using a special hand-made cutting tool to get that perfect peeling edge needed to dispense labels without tearing the backing paper. Polished with ultra-fine polishing compound so paper flows freely around the plate.

- Motors: The machine uses dual shaded pole gear motors, made in the USA, to our specifications.

Requirements for labels:

- Must be on the 3” (76.2 mm) core

- Must have approximately an 1/8” (3.75 mm) gap between labels

- Must be in copy position 3 or 4 – Copy position 3 is recommended

- Maximum roll diameter 9” (228.6 mm)

- Label must be over 2 mil (0.05mm) thick

- Length of label must be over 1” (25.4 mm)

- For 10″ (254 mm) labelling unit can be between 1 1/2″ & 9″ wide (38.1 mm – 228.6 mm)

- For 16″ (406.4 mm) labelling unit can be between 2″ and 15″ wide (50.8 mm – 381mm)

- Avoid clear cellophane backing paper. You can use it, but you must order your machine with the optional “Waste Rewinder” – this material wants to cling to the machine and get tangled in rollers.

Videos for setting up the unit :

Optional accessories :

Rewinder of the waste paper … +500 Eur

This option part automatically rewinds the waste paper that is produced after labeling your product. Without this option part the waste paper is simply fallen over the back of the machine into a waste bin.

Automatic activator … +250 Eur

This labeling option allows you to just insert your bottle and start of the labeling cycle is automatically activated. Foot switch is still included, but not needed to operation!

Reviews

There are no reviews yet.