Description

Automatic bottle labelling machine for applying of one or two self-adhesive labels on the bottles

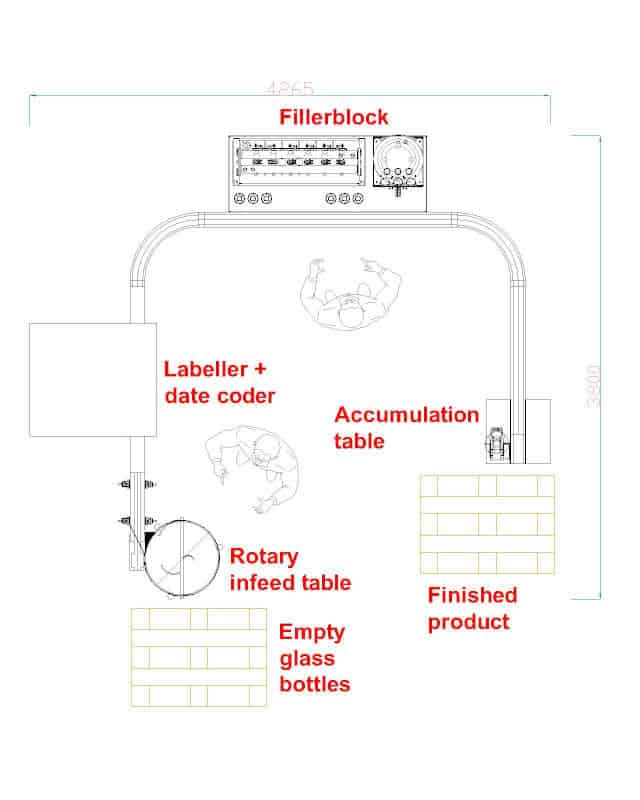

Linear bottle labelling machine (variable speed motors)

Operation capacity max 1800 bottles per hour for one label (the operation capacity may be reduced in case of use long label glued around entire bottle or application of more than one label )

Suitable for labelling cylindrical bottles such as beer bottles, wine bottles, jam jars, spreads, pickles, sauces, etc

It is not possible to use this machine for labelling conical bottles.

The machine in a basic configuation is suitable for the application of one body label on every round bottles .

Variable speed motor is included for automatically adjusting the speed of inlet of the bottles to the machine – needed to synchonize the labelling machine with other machines like bottle filling lines.

On request the machine can be equipped with accessories:Automatic on-bottle notch positioning system

- Automatic label positioning system

- Accessories for the application of the counter label on round bottles

- Accessories for the application of the counter label on square bottles

- Accessories for application of the bottle neck labels

- Date printing unit

- Other accessories as per optional list.

Description :

The inlet station is equipped with a system of rubber rollers which allow a perfect adherence of the label to the bottle.

A timer device allows printing of date on the label. The date printer is adjustable in order to be able to find the right position for print on the label.

Labels are applied with an extreme simplicity and precision by means of independent heads.

The machine presents the solutions which better reflect the requirements of precision and practicality, offering automation and technology to the highest standards.

The machine is compact and robust and is suitable as a labelling unit of a bottle filling line. It can be adapted to various size bottles and labels.

The machine is constructed mainly of stainless steel and other anti-corrosive materials in order to guarantee long life and low maintenance operations.

The machine is delivere as complete with conveyor and cumulative collection table with motor which is suitable for driving of the complete small filling line conveyor (with length up to 5-6 meters) with motor 400V 3 phase.

Production capacity is from 900 up to 1.800 bottles per hour. Max. speed depends on number of labels, their size and the shape of the bottle. The speed can be adjusted with the application of the timed selection star (see optional).

The machine is also equipped with safety cabin at EU standards.

The machine is in standard configuration supplied with 1 labelling station.

Note: For version with voltage 220V 1 phase, please add 15% on the basic machine value.

Installed power consumption :

– 0.18 kW for the clamping roller motor

– 0.18 kW. For the conveyor drive

– 0.18 kW for each labelling station

– 0.15 kW. For the printing unit (if installed)

– 0.18 kW for the screw feeder (if installed)

The basic machine is equipped with drive, 1 labelling station and clamping roller, so the total consumption of the basic machine with one station is 0,54 kW

Air consumption 50Nl/min

Weight : approx. 250kg (according to accessories installed)

NOTE : The presented machine is supplied with one only labelling station. Secondary labelling station can be added as accessories.

OPTIONAL ACCESSORIES :

| Item | Description | Qty | Price |

| 0 | BLA-MB1800 : Automatic bottle labelling machine | 1 | Price on demand |

| 1 | Two labels on the same reel | 1 | Price on demand |

| 2 | Photocell – sensor of the “full belt” to stop machine | 1 | Price on demand |

| 3 | PLC + touch LCD – control computer and visual digital display unit with touch screen | 1 | Price on demand |

| 4 | Ink jet printer 12.6 mm – for multiline print of date, batch number etc. | 1 | Price on demand |

| 5 | Collection table 1000x500mm – Place for cummulation of labelled bottles before their manual unload | 1 | Price on demand |

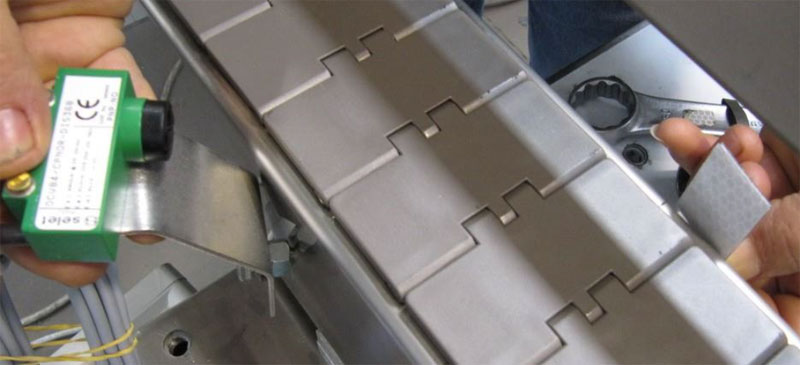

| 6 | Conveyor chain – 1 meter of the bottle conveyor (plastic or inox) | 5 | Price on demand |

| 7 | Head iddle for the chain bottle conveyor | 1 | Price on demand |

| 8 | Inverter – variable speed controller (only with PLC + touch LCD) | 1 | Price on demand |

| Total (all options) | Price on demand |

Description the options :

1. Two labels on the same reel – applicator of two labels on each bottle

2. Photocell for “too full” indication – Supplement for the installation of a photocell for avoid jam of bottles in output conveyor because the unload table is full of bottles.

3. PLC + Digital touch display – Supplement for PLC and visual digital display unit. Touch screen – simply and ergonomic control of all functions.

4. Date printing unit – Ink printer

Supplement of numbers to print date in format “dd.mm.yyyy” on labels (totaly 38 characters). Inclusive of spaces and dots.

The standard set is composed of a series of brass blocks suitable for printing a date, with single standard blocks 6x2h2mm or alternatively on request 6x3h3 mm (total 38 punches and 6 neutrals – example 31.12.2012):

Content included in the package: 4 pcs of “0” + 6 pcs of “1” + 5 pcs of “2” + 3 pcs each of “3-4-5-6-7-8-9” + 2 pcs of dot “.” + 6 blank spaces + All with height 2 mm.

6. Chains for bottle conveyor (Acetalica / 82.5 – 4.0) – Acetylic resin chain conveyor, Width=82.5 mm, Straight, Thickness 4 mm, Price per meter

7. Head iddle for the chain bottle conveyor – Conveyor idle head with shaft that is fitted on bearings, support feet included.

Reviews

There are no reviews yet.