Description

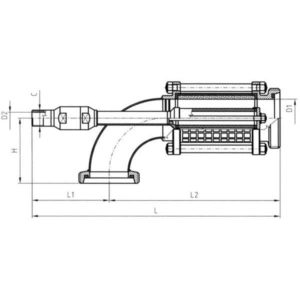

BFSA4-600 Semi-automatic filling of the bottles (from 200 to 600 liters per hour)

Technical specifications:

– Semiautomatic filling machine stainless steel made, used to bottle all carbonizated beverages, such as sparkling wines, soft-drinks, beer, mineral water.

– High versatility : possibility to fill glass and PET bottles from 330 ml to 1.5 Lt.

– Product tank with thick walls, tested up to 7 bars

– Level probe inside the tank for automatic product inlet

– Pneumatic bottle-lift with bottle centring device

– Stainless steel filling nozzle, with seals sterilizable with hot water or Steam on request

– ‘No-foam’ filling system, with rubber ring on the filling pipe to spread the product on the bottles walls

– Product level inside the bottle by means of steel pipes, easily removable with a tool included in the supply

– Front safety panel with pneumatic safe lock

– Pneumatic operated unit

Bottling cycle:

1. Positioning of the empty bottles on the pedestals

2. Closing of the front safety panel

3. Bottle-lifting up to start the filling cycle

4. Automatic filling cycle with first phase of pressure exchange between the product in the tank and the bottle

5. Filling operation with automatic levelling

6. Controlled ‘degassing’

7. Lowering down of the full bottles

PRE-VACUATION SYSTEM

Optional accessory – When the bottle is lifted up against the filling valve, to get an efficient vacuum the air is sucked out from the bottle by a ‘venturi’ system. The operator has to shut the vacuum system by a lever and then open the valve to start the filling operation.

Technical parameters

- Weight : Kg. 150

- Dimensions : cm 100x48x176 h

- Output : approx 300-500* bph based on 330ml & 200-400* bph based on 750ml

- Product tank pressure: 3 to 3.5 bar average and 5 bar Max limited by safety valve

- Compressed air : 6 bars to the machine and 30-40 lt/h according to production

- Power : Connect to Single Phase 220 V 50 Hz – 0,25 Kw

*N.B.: the output will vary according to Volume to be filler, Product filled, CO2/gr. Content, Filling Temperature and Filling Pressure.

Optional accessories :

- Stainless steel set of pipes for changing the product level … 75 Eur (price for each – there are needed 4 pcs)

- Dummy bottles including predispotision for CIP (full set for each valve) … 690 Eur

- Pre-vacuation system (full set) … 3780 Eur

- Automatic upgrade – Version of machine with PLC and automatic filling … 1780 Eur

- Bells centering (different neck) – Set of neck centering bells for different size neck … 780 for each

- Level adjustment tubes – Stainless steel set of pipes for changing the product level … 195 for each valve

- Installation – Installation, start up and commissioning (only for Europe) … 1700 Eur (transport, accomodation are not included)

Reviews

There are no reviews yet.