Description

Operation capacity: 150-250 bph (depending on fill temperature and the operator, calculated for bottles 330 ml)

Designed for : natural or carbonizated beverages (beer, wine, cider, soft drinks, water)

Type of bottles : Glass bottles (330 ml or 750 ml)

This machine is an original Czech made product.

Description :

- Suitable for the filling of carbonized wine, beer, cider, soft drinks and water in glass bottles.

- The lifting of the bottles is done pneumatically using an integrated air compressor.

- Contact parts made from 304 stainless steel

- Stainless steel support table

- Transparent protection guards to ensure maximum safety for the operator in case of bottle breakage.

- Special filling nozzle to reduce foaming comes as standard

- Usable for the filling of glass and PET bottles

- Machine on 4 wheels, to make machine moveable.

- Follows CE regulations

Description of the operation cycle :

- The operator manually inserts, empty bottles upside down into the throat of the nozzle which is used to sanitize bottles.

- After pressing the button, the bottle is cleaned and sanitized by sanitation solution. The sanitation sequence is automatically, consecutively repeated 3 times.

- Subsequently, the operator removes the bottle and positions them on the table under the filling needles (depending on the size of the bottle, it is possible to adjust the height of the table under the filling needles, so that the filling needles be fully inserted to a particular bottles – setting of the table is done manually) .

- In the next step by pressing of button “filling” needles go automatically down and land on the bottles. If the bottling line works properly, the operator has always achieved the same level of beverage in all filled bottle, which is done by special design of the filling needles.

- Subsequently, the operator removes the filled bottles and put them on the table. Then the crown caps will be applied on bottle using an integrated machine to capping of bottles.

The basic functions of filling machine:

- Rinsing of the bottles by sanitizing solution

- Beverage filling into bottles

- Capping of the bottles

Technical specifications of the machine:

- Bottles are rinsed by sanitizing solution before beverage filling. Rinsing process is automatically done after the operator push the button “rinsing”.

- Sanitizing solution is mainly based on oxygen. Bottles are manually inserted into the rinsing dishes with spraying nozzles upside down.

- After rinsing phase, operator manually puts the bottles on a table under the filling nozzles.

- Bottling machine has four rinsing nozzles and four filling head with filling nozzles and one pneumatically operated head to capping bottles.

- Usually operator can use the bottles with volume from 330 ml to 750 ml, in case of a larger volumes it is necessary to consult it with the manufacturer.

- Level of the beverage in the bottles can be set individually. Design of the filling nozzle ensures that all bottles will be always filled on the same volume of the beverage.

- It is possible to fill natural beverages or carbonated beverages (like water, mineral water, lemonades, beer, cider, sparkling wine) directly from the tank.

- The bottling line is equipped with a diaphragm pump, which pumps the beer from the serving tank to the integrated buffer tank of the bottling machine (the amount of beer in the storage tank is monitored by level switches) if level in the storage tank drops to a minimum level then pump automatically starts to drawdown the beverage from external tank.

- Pressure in the storage tank of the bottling line is set by the user according to the pressure in the beer tank.

- Line is designed as movable with 4 stainless steel casters with possibility to be braked on place.

- Capping head – for crown caps – it is pneumatically operated.

- Phase of rinsing, filling and capping is performed automatically after pressing the button by operator, refilling of beer storage tank is done automatically.

- Bottling line is equipped with very quiet oil-free air compressor.

- Material AISI 304 – stainless steel.

- Connection of the bottling line with an external beer tank by flexible hose – the hose is not included.

- Type of connection can be customized – either clamp, DIN or SMS.

- Machine can be completely sanitized (washed) within the sanitation process that allows complete washing and sanitizing all routes, hoses and pipes of the machine.

- Well trained staff is able to fill the from 200 up to 250 bottles of 330 ml per 1 hour.

Parameters :

Parameters :

- Output 150-250 bottles per hour depending on fill temperature, type of the bottles and the operator

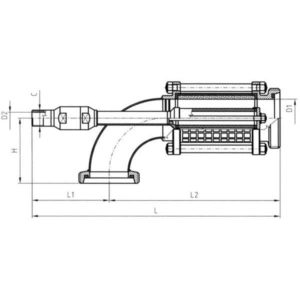

- Bottle specs: Max diameter 120mm – Max height 350mm

- Power connection : Single phase 230V / 50Hz

- Power consumption 0.37 kW

- Air consumption 6 bars – 120ltr per minute

- Dimensions: 0.88m x 0.74m x 2.37(h)m

- Weight : 120kg

Parameters :

Parameters :

Reviews

There are no reviews yet.