Description

Monoblock with automatic rinsing of bottles – isobaric filling of bottles – capping of bottles – with electronic valves

Hourly output:

– 500 bph 0,5 lt * (one degassing)

– 550 bph 0,33 lt *

– 450 bph 0,75 lt *

Further degassings and gas injections will take up more time!

Filling temperature: 0°C – 4°C

Machine: Stainless Steel AISI 304.

Plastic safety guards for the rinser and for the crown capper.

Operating cycle:

The operator of the machine carries out the operation of loading and unloading of the bottles on one side of the machine.

The bottles are picked-up by pneumatic clamps. They are rinsed with water, which is poured into the drain. (Alternatively, with special optional device is possible to carry out in a different way).

In the end of this phase the bottles are repositioned on conveyor belt. They move to the part with the filling heads.

Process phases:

1) Air degassing from the bottles through a vacuum pump (one or two) ;

2) Bottles pressure balancing through injection of inert gas ;

3) Isobaric filling (safety wire mesh is not placed on this machine) ;

4) Discharge of pressure ;

In the end of the filling cycle the bottles are transported by a conveyor belt to the front part of the machine (the operator’s side).

Power supply:

Electrical : 1,0 kW 400 V. Hz3F+N+T

Pneumatic : Compressed air 6 BAR

Air consumption : 400 Nl with 3/8” female thread – Rilsan pipe 10mm

Water (bar): 3,5 with ½” female thread

CO2/N : cylinder with reducer 2,5 Bar with 3/8” inner thread – Rilsan pipe 10mm

Product Connector : DN 32 female thread

CIP Connector : DN 32 female thread

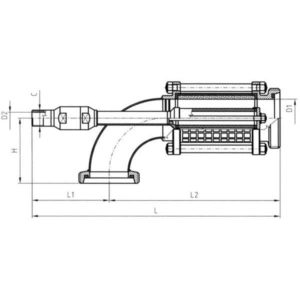

TECHNICAL DATA

– Maximum diameter : 100mm

– Maximum height : 340-370mm

– Machine dimension : cm150x120x200 h

– Weight Net : 700 Kg

* just informative

Optional accessories :

- Equipment for another crown cap – Ref: Crown cap – extra size … 550 Eur

- Fobber (evacuator): prior to capping (mechanical) – Ref: Fobber (mechanical) … 275 Eur

- Fobber (evacuator): prior to capping – Ref: Fobber (water spray) … 275 Eur

- Equipment for level variation (5 pcs) – Ref: (Level adjustment tubes) … 235 Eur

- Equipment for extra large round bottles – Ref: Round bottle – extra size 5/5/1 … 2880 Eur

- Volumetric injection of Sugar Solution for the second fermentation – Ref: Inject (syrup) … 3550 Eur

- BLA-MB1000 Automatic monoblock labeller … 6800 Eur

Reviews

There are no reviews yet.