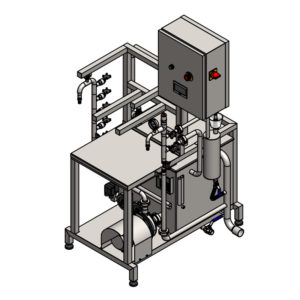

Description

Industrial counter-pressure bottle filling machine and carbonator for all beverages. This device is designed to filling beer or cider under pressure as well as carbonating and bottling of all kinds of non carbonated beverages in only one movement . Intended for all common beverages like sparkling wines, fruit juices, ciders, waters, etc. Operation capacity: up to 250 bottles/hour depending on the bottle size.

Main features :

Consistent carbonation level – by keeping a set temperature and carbonating pressure the BCF model produces consistent levels of carbonation and ensures the product cannot be over carbonated.

Fully integrated carbonator and counter pressure filling mechanism – the single unit ensures reliable performance and consistent quality of beverage .

Suitable for a wide range of bottles and cans.

Fully adjustable carbonating range – from 2.0g/L to 8.0g/L CO2 content .

Suitable for both carbonated and still beverages – enabling the development and trial of a wide range of products.

Compact – a footprint of 0.6m x 0.6m and a height of 2.2m.

Robust – constructed in high quality stainless steel.

Simple and efficient – easy to change bottle sizes for production runs of as little as 5 litres.

Cost effective – low maintenance and operating requirements.

Suitable for filling PET bottles as well as glass bottles of capacity from 0.2 to 2 litres

Simple to operate.

Capable of carbonating beverages at normal ambient temperatures!

Dimensions: 50 x 50 x 240 cm.

Power supply: 220 V, 16 A.

Additional features

- An additional in-built chilling cool can be incorporated into the carbonating chamber in order to reduce or maintain product temperatures if required.

- The CW400 mono pump model includes an automatic CIP function.

| Technical Specification | BCF-250 | BCF-400 |

| Maximum capacity of beverage | 250 bottles per hour | 400 bottles per hour |

| Max. CO2 (N2O) content in beverage | 12g/ltr | 12g/ltr (10g/ltr) |

| Maximum carbonating overpressure | 0.8 MPa | 0.8 MPa |

| Max. CO2 consumption (based on 1 ltr bottle) | 4kg/hr | 4kg/hr |

| Capacity of bottles | 0.2 – 2.5ltr | 0.2 – 2.5ltr |

| Adjustable bottle height | 180 – 340mm | 180 – 340mm |

| Bottle Pitch | 140mm | 140mm |

| Number of Filling Valves | 2 | 2 |

| Power demand | 1kw | 1kw |

| Feeding | 230 (3×400) V, 50 Hz | 3×400 V, 50 Hz |

| Noise Level | 60 – 75 dB (A) | 60 – 75 dB (A) |

| Weight | 130 kg | 150 kg |

| Dimensions | 0.6 x 0.6 x 2.2 m | 0.75 x 0.6 x 2.1m |